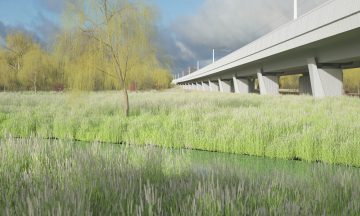

Edgcote Viaduct

Set low into the landscape, the 515-metre-long Edgcote Viaduct will carry the railway across the floodplain of the River Cherwell, south of Chipping Warden.

Viaduct construction

Our Edgcote viaduct team, Eiffage Kier Ferrovial BAM JV and FC Civils Solutions, has achieved the key milestone of installing the final of 40 piers on the 515-metre-long viaduct in West Northamptonshire. The 70-tonne piers are manufactured by pre-cast specialists PACADAR in Kent, before being transported to site. They are then carefully lifted into place by two cranes using a tandem lift. One crane lifts the pier horizontally, while the other rotates it into a vertical position and installs it over the pile cap. The final design of this viaduct uses two beams per span compared to the original design which used five. This change has allowed the teams to speed up the construction process and reduce the viaduct’s carbon footprint. Edgcote uses the same design approach as Thame Valley Viaduct, its sister viaduct near Aylesbury. The construction teams are in close contact and have implemented many lessons learned as the works have progressed.

Viaduct design

A major construction milestone has been reached on the Edgcote Viaduct in West Northamptonshire, with the final pier now successfully installed. The structure, which will span 515 metres once complete, is being delivered by the Edgcote viaduct team — a collaboration between Eiffage Kier Ferrovial BAM JV and FC Civils Solutions.

Each of the 40 piers weighs around 70 tonnes and is precision-manufactured off-site by pre-cast specialists PACADAR in Kent. Once transported to site, the piers are lifted into position using a tandem crane operation — with one crane lifting the pier horizontally, while a second rotates and lowers it vertically onto the pile cap.

The viaduct’s final design features two beams per span — a significant improvement from the original five-beam design. This streamlined approach not only accelerates construction but also reduces the carbon footprint of the structure.

Edgcote Viaduct shares its design approach with the Thame Valley Viaduct near Aylesbury. The two teams remain closely aligned, regularly sharing lessons learned to drive innovation and efficiency across both sites.

Key facts

- Length: 515m

- Height: 8m

- Number of piers: 38

Keeping you informed

Stay informed about the works

Find information about HS2 works and activities taking place in your area.

Managing impacts of construction

Find out information about how we manage construction impacts.

Construction look-ahead

Read our three-month lookahead for associated work in Northamptonshire.

Find out what HS2 means for Northamptonshire

This section provides you with information about HS2 works and developments in your area.

Find out more