How to build a railway: Episode Three – Preparing the ground (transcript)

This is a transcript of episode three of HS2’s How to build a railway podcast, first published on 14 March 2023.

Fran Scott: I’m Fran Scott Scott and this is How to Build a Railway.

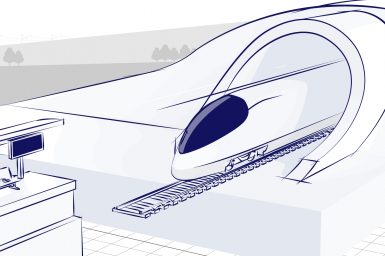

Everyone knows that High Speed 2 is a project of superlatives – over 200 miles of line when all phases are complete… trains capable of speeds up to 225 miles per hour, carrying hundreds of thousands of passengers per day… and some tens of billions in investment.

But what we might not know is how much work needs to be done before the phase known as ‘Main Construction. The workforce does just not show up at virgin sites and start laying track.

These enabling works cover everything that needs to be done before building the stations, bridges, tunnels and track that make up the main project. This means, for example the archaeological programme, and the ecological studies and other impact assessments for HS2’s Green Corridor… but also everything to do with site investigations, works permissions, stakeholder engagement, land clearances…

“Decommissioning, demolitions, ground treatment, roadworks, bridge strengthening, utility diversions, habitat protection, tree planting…”

Carrying out this work is a megaproject in itself and in this episode we will look at developing the Ground Investigation programme, we will look at demolitions, we will look at utility diversions, and we will look at provisioning power to feed the project’s future tunnelling operations.

…and all that will just be scratching the surface as we learn about how High Speed 2 went about “Preparing the Ground”.

1:58

Jonathan Gammon: When I started at HS2, there was a team of one, there was just me. Peter Lynch was my boss at the time. And he was fantastic. He was really encouraging really good. But after a few days, where I kind of settled in, and we were looking at various documents that needed to be produced. He said, “well, what we really need is a team”.

Fran Scott: This is Jonathan Gammon, currently working for Geotechnical Observations Limited, but back in 2014 he was tasked with designing a ground investigation programme for High Speed 2, Phase One of HS2 – the section of the railway that will run from London to Birmingham.

And if you are wondering what the second most extensive programme is… well, that would be Phase Two.

2.39

Jonathan Gammon: By an extraordinary stroke of luck, and this is the only time it’s happened in my career, a group of engineers with various different backgrounds had come off the Northern Line Extension Project, which essentially come to an end in terms of their involvement. And I think they were very much wondering what to do.

Fran Scott: He met with the head of the geotechnical side of CH2M at 7am on a Friday morning. By lunchtime he had decided on a team structure.

3.05

Jonathan Gammon: That team were 14 stayed in place until towards the end of the year, when much to my delight, because we didn’t expect this. we were asked to continue in that role and move on from doing the design of the ground investigation through to its implementation.

Fran Scott: Megaprojects tend to face outsize delays if tasks on the critical path are slow. Jonathan knew that he was embarking on the largest ground investigation programme in British history, and he needed to get moving.

3.38

Jonathan Gammon: At that time, when we’re talking February, March 2014, there was a pretty firm idea as to what the alignment would be. So that that helps hugely.

Fran Scott: Not a precise, final route, but a narrow corridor in which it would remain.

3.54

Jonathan Gammon: And so we were able to identify where there was likely to be tunnelling works in broad terms, tunnelling works viaduct structures and earthworks in terms of cuttings and embankments.

Fran Scott: So they set themselves the task of identifying the most appropriate type of investigation all the way from Euston Station in London to Curzon Street in Birmingham. To a degree they were dictated to by the Eurocodes that were in effect.

4.20

Jonathan Gammon: There’s a requirement, there’s a minimum requirement for information in terms of spacing of exploratory holes, so that might be a borehole. We have all sorts of different techniques, but trial pits, which are very basic shallow excavations to look at the ground to shallow depths, but also bore holes.

Fran Scott: There is a whole suite of techniques, modern and traditional that offer a picture of the subsurface.

4.45

Jonathan Gammon: I think really the exciting thing many ways from a geology point of view we’re actually cutting across the geology, the main formations in England. So it’s very exciting from that point of view. So, as we go up towards Birmingham, we actually bounce through these different geological formations, and we have to investigate them accordingly.

Fran Scott: Our whirlwind tour of the geology along the High Speed 2 starts with the wonderful blue clay, or London Clay, of the Euston area!

5.14

Jonathan Gammon: …thankfully, because that’s a great tunnelling medium, and it explains why most of the London Underground system is north of the Thames, because that’s where the London clays at its greatest thickness, and why it’s been difficult to tunnel south of the Thames because you get into the lower formations, those formations underneath the London clay, which are more sandy and gravelly and more difficult to tunnel through. You go into the chalk, and then you go into the older formations, , as you get towards Birmingham. As you run north, you’re actually cutting across the tops of these different ages of, geological formations.

Fran Scott: Spacing boreholes along these slices of geology is dictated by the importance of a particular location to the project. A shaft or tunnel portal site needs to be better understood than a stretch of surface track out in the country.

6.02

Jonathan Gammon: When you get to the viaducts you might be wanting to look at where the piers are expected to be. But that in itself is a difficult process because those locations can change. They can change in the hands of the contractors further downstream in the design process when they come on stream and do their own design work. So, what we really wanted to do was to convey a pretty sharp picture as to what the geology was like, respecting the spacing requirements but also having an eye to the fact that in doing that, we were going to end up with something like 12,000 fieldwork locations.

Fran Scott: Twelve thousand investigation sites, but there could have been much more. The programme was refined down to where the team was more confident in the ground conditions and where they weren’t expecting significant design changes.

It was also important to parcel the route up in such a way as was logical to the construction that would eventually be done. Each zone would be let to a different ground investigation contractor.

7.03

Jonathan Gammon: We needed to make sure that that information would join up properly, that there wouldn’t be this disjoint when you put one geological interpretation, or infer, geological cross section against another. We needed to make sure that the investigations suited the way in which the work would be divided up. And that was actually a very difficult process.

Fran Scott: With the programme designed, all that was left was to get approval and funding to move ahead.

7.26

Jonathan Gammon: And I would say, but with great care that the best Christmas present I’ve ever had, other than the presents my wife, of course has given me was the 70 million pounds that was put in my hands by Her Majesty’s Treasury on the 17th of December 2014. And told: “get on with it”.

Fran Scott: Once Jonathan and team had completed the preliminary studies and presented Bills of Quantities to the subsequent ground investigation contractors, the detailed investigations could begin.

Ground investigation is not just about geology, especially in the urban environment. And one of the most complicated areas of the project is around the southern terminus – Euston Station.

8.15

Laura Hughes: I’m Laura Hughes. I’m the country director for Fugro in the UK, and I have particularly responsibility for our Landside Characterisation business. I am a chemical engineer by background, and I’ve had a 20-year career in the energy sector. And I’m running our ground investigation business.

8.37

Dave Thomas: I’m Dave Thomas, I’m the UK CPT Manager. So, I look after cone penetration testing in the UK. I’ve been with Fugro for about 15 years now. And early on in my career, I used to work on site as a geotechnical engineer and I was actually the site manager for the Euston station throat ground investigation.

Fran Scott: Cone penetration testing is one of the fundamental tools in the GI contractor’s kit. It is the process of advancing a calibrated cone into the ground, and while it penetrates, the pressure on the tip and the friction on the sleeve are digitally measured and recorded.

The combination of those two measurements tells us how soils are going to behave, either like a sand or a gravel or a clay. It’s an ingenious and simple test.

But Euston would require the full range of techniques developed by the sector.

9.36

Laura Hughes: A very, very complex built environment where HS2 wanted to start the process of really understanding the area in which they were going to have to develop and design and then construct the new infrastructure associated.

9.51

Dave Thomas: The aim of the investigation on the first part of the Euston station throat contract was to be able to build a fully detailed three-dimensional map of all of the services that lie underground.

Fran Scott: This could include gas pipes, electricity lines, water, communications, tube lines… the subterranean environments of cities, and especially old cities, are a spaghetti of services! 10.20

Dave Thomas: And we started the process by building the base map. So we did a topographic survey of the pavements, the streets, the kerbstones, trees and street furniture, to build that base model on which we later built up the service information. So once we’ve completed that base model across 44 streets in London, very central London, two and a 2,500 square metres of survey, we then started to look beneath the ground and started to investigate what was happening with the services.

Fran Scott: They started by lifting up service inspection chambers and sketching what was lying down there, and scanning any ducting or cables that lay there to get their depth, diameter, and surface orientation.

11.05

Dave Thomas: We then plotted all that information onto the model we’d already built. And then it evolved by adding a ground penetrating radar survey. So we carried out a ground penetrating radar survey on the footpaths and in the highway to cross reference that information we’d already gathered to ensure that we’d obtained the service information using two different techniques to ensure it is as accurate as possible.

11.34

Laura Hughes: You’d think that in an area like Central London, that someone would know where everything was, but actually, it’s not the case, the information that we hold under those different information banks in the UK, and I think in any urban environment that’s been developed over centuries, that information is really imperfect. So you can’t pick up a map of any London street and know exactly where the gas name was run, where the electricity lines run, where the fibre optic lines were uneven, that have been quite recently installed. So that the beginning of the whole of the development story is starting to say, “well, actually, we don’t have a definitive, perfect picture of what’s there”. So we have to start by sort of peeling back the layers to form that model. So that then designers can, with a very high degree of confidence, know what is in the ground under our feet.

12.38

Dave Thomas: We combined all that information together, and then could give a confidence level as to how sure we were about where each of the services were. That was the main deliverable to HS2, this three-dimensional CAD model of all the services. But we then took it another step further and imported that into the augmented reality world, which enabled our staff to be able to look through a tablet, and using the GPS, the GPS coordinates of the tablet, to be able to see what those services were doing underground.

Fran Scott: This is the first time Dave had seen augmented reality even considered for a ground investigation project, and being able to point a tablet at the ground and see the layers beneath it was…

13.29

Dave Thomas: Quite visionary and I think it’s still something that is evolving and emerging. It’s certainly not in common use yet as a technique.

Fran Scott: Another difference between investigations today and those in previous decades is sensitivity towards the environment. And this means something different depending on where the investigation is taking place.

In Euston, emissions and noise from the rigs and drills are incredibly important. It is also essential not to drill into – and potentially contaminate – aquifers that supply the capital’s water.

14.03

Dave Thomas: So in this project, we set aquifer protection between each of the permeable layers to ensure that that contamination couldn’t permeate down into the into the groundwater. It involves setting a seal of an impermeable material when you change between permeable lithologies. And we reduced the size of the drilling string we’re using to set that seal between those lithologies. And basically, it means there’s a physical barrier between the made ground at the top and the chalk at the bottom of the hole. We also did some work on this project into evolving the kind of drilling fluids that we use to help lubricate the core as we drill down to ensure it was the most environmentally sensitive and environmentally neutral drilling polymer on the market.

Fran Scott: Once the ground was understood, work could begin to divert utilities and clear a number of buildings that would obstruct the future station and tunnel construction.

15.09

Danny Allen: From the south we had there was probably a just over 30 buildings which needs to be demolished and included an 18-storey and a 10-storey tower block right outside the front of Euston station, adjacent to the piazza and the station.

Fran Scott: This is Danny Allen, a Senior Project Manager for Enabling Works at Euston Station. His work covered the immediate station, and then a corridor to its west, where demolitions were complicated by buildings being connected to listed buildings.

As with the underground services, buildings can also have some surprises. For example, unauthorised basements.

15.52

Danny Allen: Yeah, we had buildings which had additional basement extensions, which had didn’t have sort of planning approval or building control approval had been just carried out by the building owner, which went underneath the footpath, which made life interesting with the utilities that are around those as well.

Fran Scott: These get removed very carefully because of the dangers around it not being built haphazardly and without proper approvals.

16.19

Danny Allen: Fortunately, in that area, it was an area that we’re clearing quite extensively anyway. So we’re able to remove it and not have to pay anything back straightaway.

Fran Scott: Even when everything has been done to code, London’s architecture can be… haphazard? Which makes dismantling it safely a challenge.

16.40

Danny Allen: We have one building, which effectively was extended four times. And, you know, a significant six storey building, which extended four times. And so to do that demolition, and to work out structurally how you can remove bit different parts of it… it was quite challenging which bits you can take down and when, which bit holds up which other bit.

Fran Scott: There was another building with a 3.5m-thick first floor slab. The team had two, 45-tonne machines sat on the slab just breaking away at it to remove it!

17.12

Danny Allen: It had 10 layers of 50 mil diameter reinforcement in the top, which was just crazy amounts of reinforcement. That was holding up an 18-storey building that was built off that as a transfer snap that actually then transferred through four 2m diameter columns, which then went into a 49 pile, pile cap, which is four and a half metres thick, which we’ve had to break out as well.

17.41

Richard Crathern: Incredibly, you find buildings that you assume the owners have pretty good idea of what they are, and they’ve just been lost over the years.

Fran Scott: This is Richard Crathern, like Danny he is a Senior Project Manager for HS2, and was involved with enabling works around Euston.

He was amazed by a building owned by the University of College London.

18.03

Richard Crathern: Had only been used by UCL in the last few years and converted into an educational facility. When we eventually did all the work on that way and traced that back it had been originally built as a tire storage, sort of warehouse. So of course, the enormous weight of all these tires and massive floors with tonnes of rebar in…

Fran Scott: Totally over-the-top for what was a fairly ordinary looking educational building… but turned out to be the most robustly built classroom the team had ever encountered.

Richard had to engage in a lot of utilities diversion work.

18.43

Richard Crathern: Whenever you cross a big obstacle like a river or a railway, all the utilities tend to get sort of funnelled through these arteries, if you like.

We always call the drawings, a bit of a rough guide, really, as soon as you open up the ground, you’re there changing everything, all the plans, you’ll find that you know, things like on identified utilities have a real pain in the neck, because no one will admit to them, you’ve got to basically find either end of it, which is a lot harder than it sounds. And then, you know, declare it redundant or find the owner. And we’ve had quite a number of instances of that more than you perhaps you think there’s a lot of abandoned stuff that’s just unrecorded.

Fran Scott: This is a problem throughout the capital. Heading further down the line to the west, Carl Ainley is Utilities Project Manager at Old Oak Common.

In his zone, three major UK Power Networks cables have been identified as old, fragile… and at risk of damage from any settlement caused by future tunnelling works.

19.50

Carl Ainley: If our ground movement are those contours of say 50 metres apart with that to say, we just need to replace 50 metres of this 66,000-volt cable, UKPN’s answer is no, you have to go back to the nearest joint, and the joints could be 200 metres apart.

Fran Scott: This extended utility works takes them outside of the limits of the Act of Parliament which lets them conduct the works. They are in the highway, so the ‘New Road and Street Works Acts’ apply.

Which is fine, they are allowed to do those works as a result…

20.23

Carl Ainley: But it just sort of causes other problems that when we’re outside of Act limits, it’s different engagement to different people, different concepts, for example, and how we procure the works. So yes, what we thought was 50 metres three times has now become 200 metres three times, if not more.

Fran Scott: Then the actual works need to be done. And this means trenching the roads for the entire length of the utility. And even though efforts are made to minimise the impact and ensure multiple roads are not affected at the same time… this is an incredibly disruptive activity for travellers.

20.56

Carl Ainley: The key really is all in the surveys and the design, really. So we’ve got to find a route.

The there’s not always a space within these London roads, they are full of lots of old apparatus. Not so new apparatus normally knows what it is you find the cable, you don’t even know if it’s dead or alive, you then have to stand the team down, you have to go through a process to spike it to check that it’s probably dead. And that might, you might lose some more time in doing that there. So we’ve got to find a route from end to end. So first of all, we do those ground penetrating radar surveys. And if that’s manhole covers, we do all the checks of the as-built records and things and some of those are pretty well out of date or incomplete. So you pretty well, starting from, well, we don’t really know what’s in this road. Let’s find out bit by bit. So that takes quite a long time to do all those designs and surveys and piecing together a route.

Fran Scott: Then there are design reviews that need to be signed off by the utility owner and any other stakeholders.

For example, many of these utilities are funnelled through key arteries, such as Network Rail bridges. So that means the team needs to go through another major organisation’s procedures and design approvals.

22.04

Carl Ainley: Then we have to procure the works. And that’s sort of the straightforward bit through there. But then when it comes to doing the works on the ground, we actually have to sort of duct from one end to the other over that 200 metres distance perhaps pretty well parallel to the existing and then we have to sort of open up a joint bay which might be the size of a double decker bus. Some of these big extra high voltage cables a joint base are literally 12 metres by three or four metres wide. They are big, which for me relates to the footprint of a double decker bus. Well, you try find the footprint of a double decker bus of clear space in a London Road where you can put these joints in which are pretty well the size of not quite as big as dustbins, but they are pretty big on a cable that is probably about four or five- or six-inches diameter.

Fran Scott: All of the ducting and trenching, and the reinstatement of the roads can be done by HS2, but the work on the utilities themselves is done by specialist teams (from UK Power Networks for example). This is paid for by the project, and often means some very old assets get a much-needed replacement.

23.07

Carl Ainley: But this is all part of the process of getting utility companies on board, because we’re the ones that will be impacting on their assets and about how old how critical they are, where the one that’s coming along, and they’re quite happy with them doing their thing. And the ground in the ground, if it’s old and whatever, that’s fine. That’s their asset. Were the one that states disrupting that status quo, which is why we have to get their approval for doing these works.

Fran Scott: Other critical enabling works have been the movement of the Euston taxi rank, which was a Tower of Babel problem involving moving it out of the way of other works, then back again.

Another sensitive activity was the exhumation programme at St James’s Gardens Cemetery. It was in use as a burial site until the 1850s when the Burial Acts of London ended non-Royal burials within the city limits.

Even to that point, there were in excess of 60,000 people put to rest on this one site. And it was right in the way of essential works for the project.

Here’s Danny.

24.11

Danny Allen: Exhuming that volume of cemetery is quite hard. When you exhume remains, you need to shield them from public view. So, we took the decision to erect a large encapsulation structure over the whole site, which is a massive scaffold, sheeted, structure, which served to restrict the public view and it enabled us to work well in that environment, but it also protects us from the weather.

Fran Scott: As a mark of respect to the individuals and their descendants, this work has to be done by hand. Although smaller machinery is acceptable to remove what is purely soil.

Any handwork is considered hazardous on modern construction sites and risks, such as slippery conditions, must be minimised.

Fran Scott: This is Jaione Echeveste…

25.08

Jaione Echeveste: So, I look after only one solicitation the main Atlas Road substation. So, the first challenge that he HS2 came across is that so we have to launch five TBMs…

Fran Scott: She has to prepare the London power grid to support the operation of the Tunnel Boring Machines when main tunnelling in the area commences. These are incredible, mobile factories that chew through the sticky Pleistocene rock that is London Clay…

Combined with their cranes and supporting equipment, they require an enormous amount of power to operate. 45MW, the equivalent of 45,000 homes. Once operation begins, they ‘only’ needed to provision 23MW of power.

They narrowed the viable locations down to three possible options.

26.06

Jaione Echeveste: That final location is around 20-30 metres from the Grand Union canal. So it can have a quite visual impact. So obviously finding that location was the one of the first steps of the first challenge.

Fran Scott: Even so, they had to underpass the Grand Union Canal using Horizontal Directional Drilling. The HDD skirts the Grand Union Canal following the embankment, while a microtunnel will underpass the canal.

This is an amazing technique that has advanced by leaps and bounds in recent years. A rig pushes a cutting head followed by a pipe into the ground. It rotates the head and a lip biases the borehole in the direction needed.

Amazing curves and accuracy are possible even with large diameters. In this drive it runs for 400m in length and 20 metres deep in a single shot.

27.09

Jaione Echeveste: So the first asset crossing is on Network Rail Bridges and Tracks on top and later it curbs and goes follows the canal embankment. So obviously, that’s another very sensitive asset, The Grand Union Canal.

Fran Scott: These are all sensitive regions with bores up to half a metre, delivered with millimetre accuracy to get the power where it needs to go.

In enabling works, everything is about enabling main construction to continue to schedule. Some plans are made up to two years in advance to take a vital service offline for a week, or even a weekend. The critical path needs to be protected at all costs to avoid major delays.

27.59

Jaione Echeveste: So again, due to the criticality of the programme, the TBMs are launching next year, in autumn time. So obviously we have very little time to deliver these… Network Rail timescales are quite lengthy. So we are working very, very closely with Network Rail to try to shorten those timescales and have the possessions and consents in time not to affect the programme.

Fran Scott: The finished High Speed 2 project will reshape the nation’s travel for generations to come. But most of the benefits are just that – still to come – while the disruptions are here and now.

Objections to the route have ranged from the environmental (any construction impacts the countryside) to the practical (the coronavirus pandemic reduced the need to travel permanently).

Although travel is back above pre-pandemic levels and the world is hurtling towards climate catastrophe, these concerns are held strongly and in some cases spill into inappropriate and dangerous responses.

Most famously, a number of environmental protestors dug makeshift tunnels below the site of the Euston taxi rank, launching a meticulous £140,000 police operation to remove them safely.

29.16

Danny Allen: We had to dig down our own shafts adjacent to their tunnels to try and get them out. The risk of collapsing their tunnels was very high. And so we’re very, very concerned about that.

We had to go carefully, and, you know, sort of looking and trying to keep in contact with them at all times. And I know the I heard that when the last protester was taken out… the tunnel behind her collapsed within hours. And so, you know, it was, it was a very serious situation that we were dealing with. Very difficult situation. So when you’ve got protesters like that, it does make life much, much more difficult. People have the right to protest, but putting themselves in… in such a harm…

Fran Scott: Having removed the protestors safely, the team had to perform ground treatment so that the taxi rank could be put in place.

A lot of the challenges to enabling works come from the unprecedented complexity of the works delivered to never-before-seen time constraints.

The other side of it is the inherent uncertainty of dealing with the underground. Below the surface is of course opaque, and works from previous years (and centuries) have spotty records at best.

Set against this is the ingenuity of High Speed 2 and its supply chain, as well as the array of technologies available to modern construction. Here’s Laura Hughes from Fugro again.

30.56

Laura Hughes: The transformation that we are seeing in the industry is really the digital revolution. And that’s still ongoing now. So using smart ways of transferring data and processing data to speed up the path from the acquisition, to the QA QC, to the reporting to the interpretation to the modelling, and then passing that on to the client. So I think that’s one of the ways in which we’ve really seen our, our site characterisation, business transform, and continue to do so because people want more data, but they want it in a digestible way. We want it faster, and we want to be assured of the quality of it. So gone are the days of the driller manually filling in a log, which then get posted on a weekly basis into the office, which then get, you know, it’s all digitally enabled. So operators in the fields have tablets, everything’s entered electronically, we work on velocity if they have single, single entry, so that that information is then kind of swept up into the system.

Fran Scott: Jonathan Gammon says that…

32.11

Jonathan Gammon: …this is actually particularly important, I think in the grand scheme of things. The introduction of BIM was actually a godsend for us working in the ground, because it did mean we had somewhere to put our data.

I was determined that we would not present the designers with a huge number of volumes of ground investigation documents, because that’s what it would have amounted to, I mean, unbelievable volume, if you look at the volume of paperwork that’s required to submit the hybrid bill. And then and the environmental statement itself, for goodness sake, because I’ve seen photographs of what that looked like when it was printed, it’s like, wow, I didn’t want that to be the case.

Fran Scott: All the GI information – fieldwork and laboratory testing – was stored electronically and therefore easily accessed for design purposes. And if, in some future decade or century, someone comes to build upon the foundations that High Speed 2 lays now, records will be complete, and their job will be easier.

And there was one final outcome to really excite the geologists out there:

33.12

Jonathan Gammon: In the ground investigation, we identified of the geological formation, which we then called the Ruislip Bed. So we’ve actually added to the geological map as a result of the HS2 ground investigation

Fran Scott: To a geologist, this is the real deal! A new geological stratum 33m below the surface that was formed in the Palaeocene period some 56 million years ago… it was probably created by densely wooded marshland bordering a sub-tropical sea.

What more could you ask from the largest ground investigation programme in British history?

Innovation will be an increasingly important component of the HS2 story as it unfolds…

With the ground cleared and secured for development, main construction on High Speed 2 can begin. Construction of the earthworks, depots, maintenance facilities, bridges, tunnels and viaducts, and the biggest station building programme since the Victorian age. And the future of transportation in Britain.

Next time on How to Build a Railway…

34.31

Kathleen Covill: Biodiversity is declining faster at the moment than any time in human history. And particularly in the UK, we’ve got 40% of species in decline. This is an environmental project that just happens to have a railway running through the middle of it.

We’ve got over 100 plots of ecological mitigation now across the route.

We’ve got a massive scale of tree and shrub planting, and we’ll be planting up to 7 million trees.

David Prys Jones: We planted about 130 hectares of new woodland, over 300,000 trees.

We’ve got an aspiration at HS2 now to deliver biodiversity net gain.

We want to leave the natural environment in a better state than what we inherited, a measurably better state.

To learn more about HS2 go to www.hs2.org.uk or follow us on social media @hs2ltd.

Explore HS2

How to build a railway

This series features insight on the HS2 project, including huge feats of engineering such as tunnels, new stations, depots and viaducts.

Archaeology

More than 1,000 archaeologists, specialists, scientists and conservators are exploring and recording over 60 archaeological sites for HS2.